| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Place of Origin : Guangdong, China

Model Number : Stainless Steel Shaft

Brand Name : CHAOSHENG

MOQ : 200 pieces

Price : US$0.10-0.40

Payment Terms : T/T,D/P,L/C,D/A,Western Union,MoneyGram

Supply Ability : 500000 pieces/month

Delivery Time : 10-20 days

CNC Machining or Not : Cnc Machining

Type : Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Material Capabilities : Stainless Steel, Steel Alloys, Precious Metals, Hardened Metals, Copper, Bronze, Brass

Micro Machining or Not : Micro Machining

Product name : CNC Machining Shaft

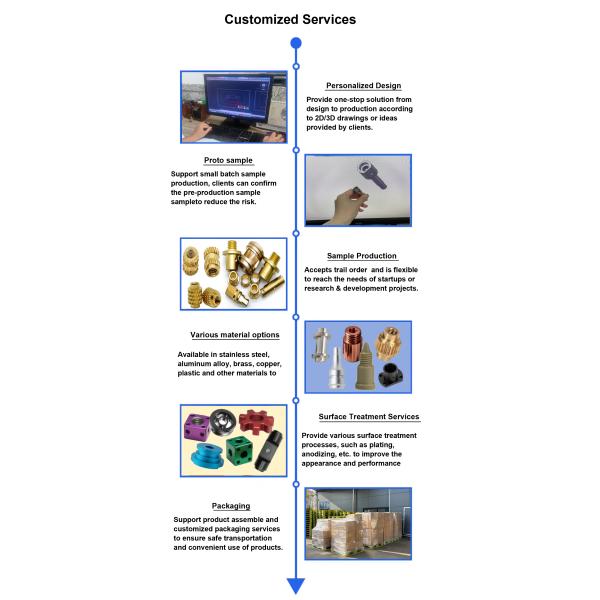

Surface treatment : Painting\Powder Coating\Plating\Polishing

Color : Customized Color

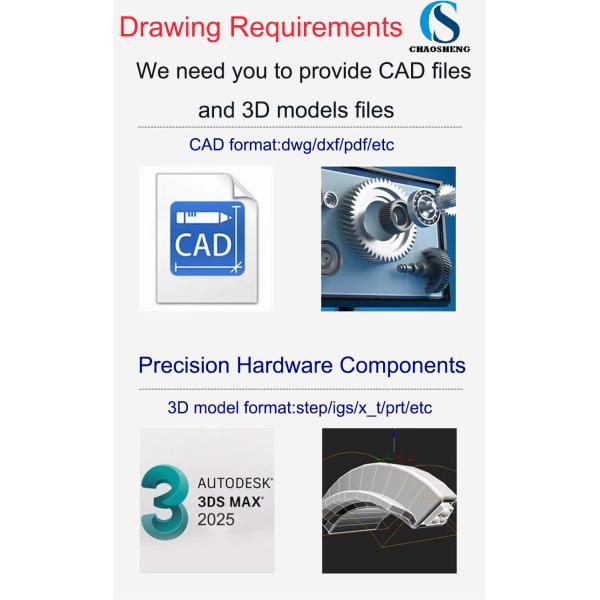

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Tolerance : 0.01- +/-0.005mm

Logo : Custiomized Logo

MOQ : 1 Pcs

Lead time : 3-15 Working Days

Payment term : TT.Trade Assurance.Western Union. Paypal

CNC Processes : Turning/Milling

| Drawing Format | IGS, STP, X_T, DXF, DWG, Pro/E, PDF, PNG, JPG | | | | |||

| Material Capacities | Metal: Aluminum alloy, stainless steel, brass, copper, tool steel, carbon steel, iron, Plastic: ABS, POM, PC(Poly Carbonate),PC+GF, PA(nylon), PA+GF, PMMA(acrylic), PEEK, PEI ,etc | | | | |||

| Surface treatment | Plating, Brushing, Polishing, Anodizing, Sandblasting, Knurling, or customer's requirements | | | | |||

| CNC processing scope | CNC 3-axis, 4-axis machining, CNC milling, CNC turning, CNC Lathe, High precision 5-Axis turning-milling combined machining | | | | |||

| Delivery | DHL, FedEx, EMS, UPS, or customer's requirements | | | | |||

| Application | Optical instrument, Automotive, Electronic device, Digital communication, Aerospace, Bicycle, Pneumatic tools, Hydraulic,Automatic Mechanical, etc | | | | |||

| Package | Tissue paper, EPE, standard carton or plastic tray, sponge tray, cardboard tray, etc., can be customized according to customer requirements | | | | |||

| 1.What's the delivery time? | | | | | ||||

| If Stock in hand: around 3 days after receipt of payment.Bulk production: around 20-25 days after receipt of deposit (may vary depending on specificitems and item quantities) | | | | | ||||

| 2.Are you trade company or manufacturer? | | | | | ||||

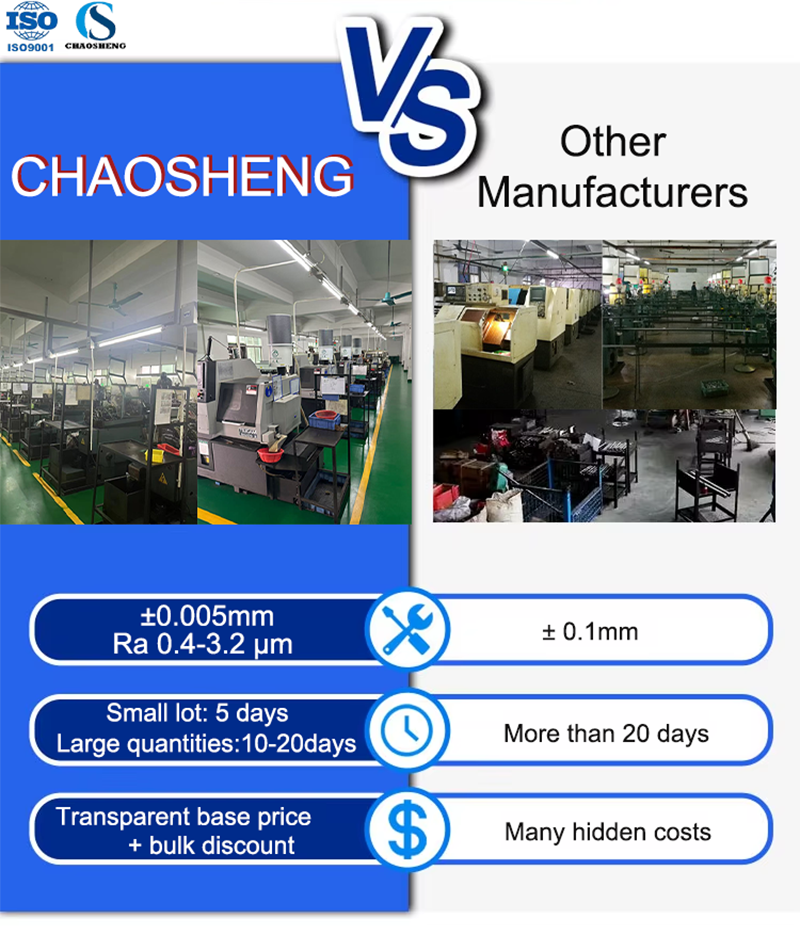

| We are manufacturing vendor with 20 years experience, warmly welcome you visit our factory | | | | | ||||

| 3.Can CNC turning produce parts with non-cylindrical features? | | | | | ||||

| While CNC turning is commonly associated with cylindrical parts due to its rotational nature, it can also produce parts with non-cylindrical features using advanced machining techniques and tooling configurations. | | | | | ||||

| 4.Do you customize products according to our design drawings ? | | | | | ||||

| Yes, we are a professional metal manufacturing factory with experienced engineering team, which can make customized products according to customer drawings. | | | | | ||||

| 5.What materials can be used in CNC turning? | | | | | ||||

| CNC turning can accommodate a wide range of materials, including metals, plastics, and composites. | | | | | ||||

| 6.What are the tolerances achievable with CNC turning? | | | | | ||||

| CNC turning can achieve tolerances ranging from ±0.001 to ±0.005 inches (±0.025 to ±0.127 millimeters) for most metals and plastics. | | | | | ||||

| 7.How does CNC turning compare to CNC milling? | | | | | ||||

| The key difference lies in how the cutting tool and workpiece interact: in CNC turning, the workpiece rotates while the cutting tool remains stationary, whereas in CNC milling, the cutting tool rotates while the workpiece remains stationary. | | | | | ||||

| 8.What are the advantages of CNC turning over traditional manual turning? | | | | | ||||

| CNC turning machines can operate continuously 24 H, without the need for operator intervention, leading to higher productivity and reduced labor costs | | | | | ||||

|

|

Broaching 316SUS Hardened Stainless Steel Shaft 5 Axis Machined Parts Images |